NEWSLETTER by Alessia Falsarone. The author acknowledges the team at The University of Chicago Circular Economy and Sustainable Business Management Program and all participants of the innovation knowledge hub for their insights and collaboration.

Carbon is an essential element of most chemical processes and of a large variety of products, from food to everyday materials. Using CO2 as feedstock can contribute to the reduction of GHG emissions. Chemical valorization of CO2 can be employed, for example, in the production of chemicals, alternative fuels, and can provide direct solutions for energy storage.

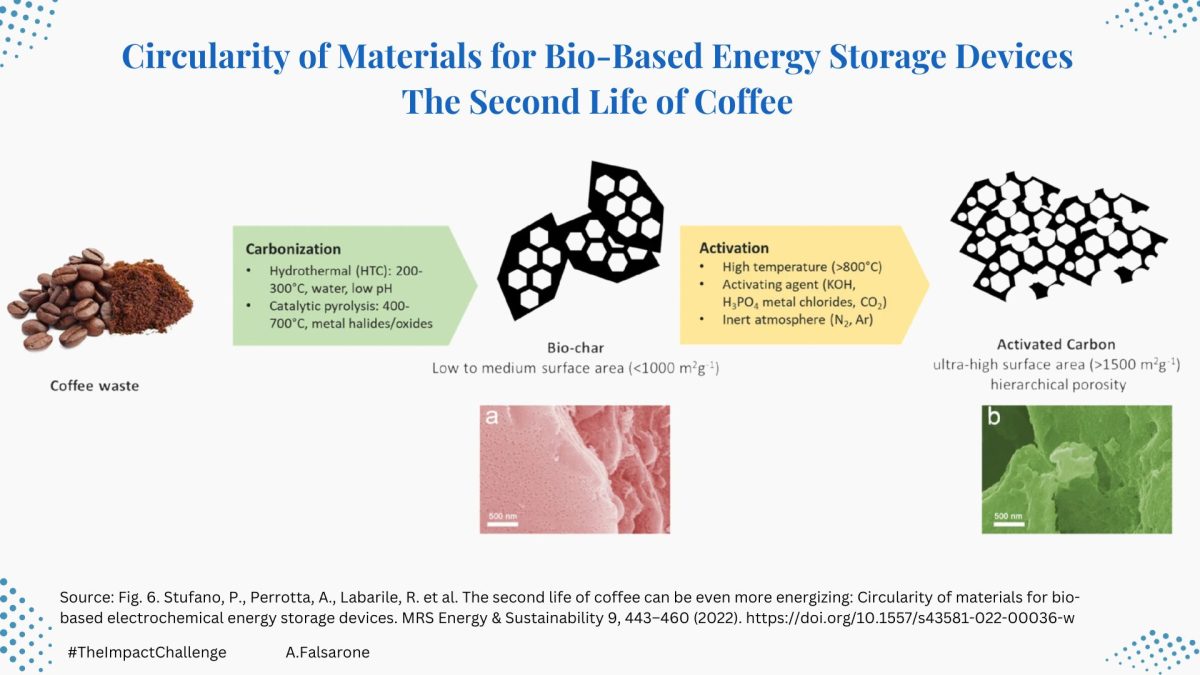

One of the valorization strategies that has been recently evaluated involves coffee wastes. Production of carbon materials for electrochemical energy storage devices such as batteries, supercapacitors, and fuel cells is likely to increase investor’s appetite for waste-derived carbon materials and the special chemical manufacturers that are entering this space.

| The science of impact

With around a billion coffee drinkers worldwide, coffee is one of the most consumed beverages globally. In the current linear production-consumption model, it is also associated with huge amounts of waste and spent coffee grounds. These wastes, instead, are recognized secondary raw materials for several circularity solutions. In fact, in the past ten years, coffee wastes have emerged as active ingredients for electrochemical energy storage devices like supercapacitors and batteries.

Researchers from the Italian Nanotechnology Institute | Cnr – Istituto di Nanotecnologia have discussed these findings while also addressing commercial viability aspects. Specifically, they point to the need to carefully evaluate consistency of materials and device performance while also taking into consideration the logistics associated with coffee waste-derived carbon materials along its entire life cycle and geographic reach.

Could circularity elevate coffee waste as a potential carbon substitute?

| Circularity roadmaps explained

Coffee is known to have the highest emissions to air and water among agricultural products, specifically due to the intensive use of fertilizers and the logistics involved in import-export transit from geographically distant countries. Think for example that, in the case of the UK, coffee imports from Brazil or Vietnam account for over 70% of the total emissions in kilograms of CO2 equivalent. Coffee byproducts, particularly spent coffee grounds (SCG) produced in the industrial production of soluble coffee or as a result of roasted coffee consumption, are garnering increasing attention as valuable sources of chemicals and materials.

One of the most fascinating emerging applications for re-using SCG is in the field of energy storage. In their early stages of development, coffee-derived carbon materials through circularity present an innovative solution that has the potential to accelerate the progress of bio-based energy storage devices.

| Investing in the Circular Economy

Specialty chemical producers are increasingly funding circularity R&D projects to improve the environmental footprint of materials through public-private partnerships.

Houston-based Orion S.A. has recently aligned funding (EUR 13 million) from Germany’s Federal Ministry of Economic Affairs and Climate Action and the NextGenerationEU fund to ‘further develop and demonstrate a climate-neutral process for producing carbon black from alternative carbon sources’.

In this case, Orion’s Clean Carbon Black Research and Development Project would bring to life a climate-neutral production process by deploying circular feedstocks. It would also test potential improvements in yield and throughput, lowering the aggregate cost of the material.

Why is an R&D project of limited funding as important?

Because its technological impact promises to be a catalyst for the molecular recycling of tires, where carbon black is used to improve the processing, strength and durability important to tire manufacturing and overall tire performance. While 90% of carbon black is currently used for rubber applications, one of its properties is also conducts electricity. Massachusetts Institute of Technology researchers have found that a 45-cubic-meter block of a novel material consisting of carbon black and cement, would be able to store 10 kWh of energy, equivalent to the average daily electricity consumption for a household.

While too early to discuss its commercial viability, it is deemed highly scalable.

In the interim, Orion is building its main innovation center at its plant in Cologne to enable a climate-neutral production of carbon black- a basic ingredient that could have a larger role in the energy transition. Direct investments in novel materials may take time to enter climate-friendly investment portfolios. Early-stage R&D by established specialty chemical producers may offer a hint of the near-term alternatives.

| You don’t want to miss this week…

From Groningen (The Netherlands) to Manchester (UK), and Rome (Italy), this week offers new opportunities to connect with fellow circularity practitioners both in person and in hybrid mode.

Discover, grow and leave your mark!

〉November 14th: Grenzeloos Circulair 2023/ Limitless Circular 2023 (Delfzijl, The Netherlands)* Held in the province of Groningen in collaboration with the Dutch Ministry of Infrstructure and Water Management, the event will focus on addressing impact of global challenges on circular export opportunities and how to start collaboration with partners in the region and internationally. Notable presenters include Arnoud Passenier (strategic international advisor, Ministerie van Infrastructuur en Waterstaat), Willem Sederel (Chairman, Circular Biobased Delta), Heleen van Wijk (business manager, Chemport Europe), and Stéphanie Schuitemaker (Holland Circular Hotspot).

〉November 14th – 15th: European Biosolids & Bioresources Conference & Exhibition (Manchester, UK). The conference provides an essential annual update on the latest innovations, best practice, cutting-edge technology and research in bioresources and biowaste processing. The program offers technical sessions along with panel discussions which focus on Circular Economy and the Role for Nutrient Recovery, Process Emissions and the Journey to Net Zero. Notable presenters include David Tompkins, a member of the team at WSP in the UK will join Dr. Yadira Bajón Fernández, Senior Lecturer in Bioresources Science and Engineering, Cranfield University, and Tamsyn Kennedy CEnv SEA, Circular Economy Lead – Research & Innovation at Scottish Water.

〉November 16th – 17th: 4th International Conference on Biomaterials & Biodevices (Rome, Italy). A must-attend event for practitioners in the international biomaterials and biodevices industry to hear about future infrastructure projects plans and government strategies, plus trends in market-leading innovation. This year’s conference will include updates related to sustainable materials, nanomaterials, and the future of nanotechnologies.

Note (*): The event will be held in Dutch only

Off to another impactful week!

| brief bio

Alessia Falsarone is executive in residence, practitioner faculty at the University of Chicago, where she leads the Circular Economy and Sustainable Business program. The article is based on the author’s newsletter A Week of Circularity from the innovation knowledge hub.

| All opinions expressed are those of the author and/or quoted sources. investESG.eu is an independent and neutral platform dedicated to generating debate around ESG investing topics.